What are the eco-friendly options for bottle packaging

We can all notice that eco-friendly bottle packaging is taking the spotlight. For beverage brands, wineries, and anyone shipping glass bottles, choosing packaging that protects without adding to environmental waste has become essential.

But what’s the best green option out there?

Why Switch to Eco-Friendly Bottle Packaging?

Traditional bottle packaging often relies on plastic or Styrofoam, which are durable but create a significant environmental footprint. These materials can take hundreds of years to break down, and, unfortunately, most of them end up in landfills or oceans. Transitioning to an eco-friendly bottle packaging option can:

- Reduce carbon emissions.

- Improve brand perception as sustainable.

- Align with environmentally conscious customers.

So, what options do we have that won’t add to pollution? Let’s take a closer look at molded pulp packaging, one of the most effective choices for eco-friendly bottle shipping.

The Eco Benefits of Molded Pulp Packaging for Bottles

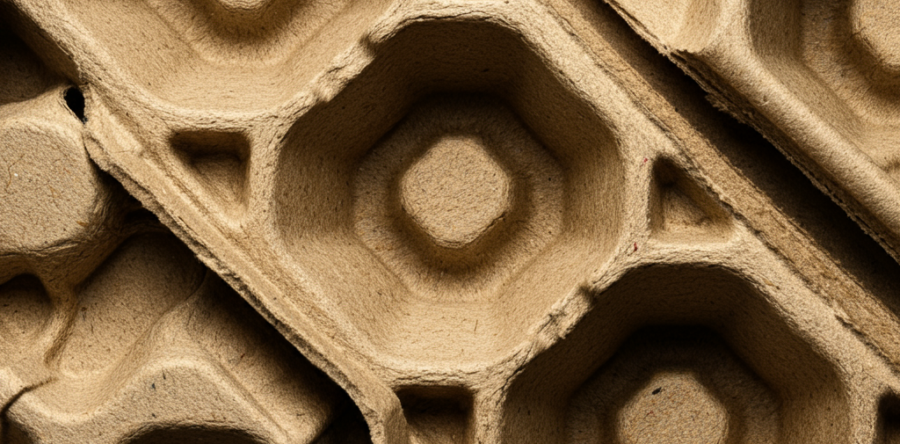

Molded pulp packaging for bottles, especially for wine, spirits, and delicate beverages, is a clear winner regarding sustainability. Here’s why:

1. Made from Recycled Materials

Molded pulp packaging is primarily made from recycled paper, cardboard, and other biodegradable materials. This means that instead of producing new plastic or Styrofoam, we're reusing existing materials. By choosing molded pulp, we’re extending the life of these materials and reducing the need for new resources.

2. Biodegradable and Compostable

One of the standout benefits of molded pulp is its compostability. After its use, molded pulp breaks down naturally and can even be composted, unlike plastic packaging, which can sit in landfills indefinitely. So, if you’re a winery shipping bottle, you’re providing your customers with an eco-friendly disposal option that doesn’t harm the planet.

3. Exceptional Cushioning and Protection

Protecting bottles, especially glass ones, requires reliable cushioning to avoid breakage. Molded pulp inserts fit snugly around the bottle, absorbing shocks and vibrations during transit. This means your product reaches the customer in perfect condition, without relying on non-biodegradable padding materials.

4. Lightweight, Cost-Efficient, and Space-Saving

Molded pulp is surprisingly lightweight, which can reduce shipping costs and fuel usage—a win-win for brands and the environment. Its stackable and compact design also helps save space, making it easier to store and transport.

Additional Eco-Friendly Advantages of Molded Pulp Packaging

On top of the basics, molded pulp packaging offers more eco-friendly perks:

- Energy Efficient: The production of molded pulp packaging requires less energy than creating plastic or Styrofoam alternatives.

- Reusable by Consumers: Molded pulp inserts can be reused by customers, especially for DIY or storage purposes. It’s a small but impactful way to extend the life of packaging materials.

Comparing Molded Pulp to Other Sustainable Packaging Options

When thinking about eco-friendly bottle packaging, other options, like cardboard or bamboo, might come to mind. But molded pulp has some unique benefits over these alternatives:

- More cushioning than cardboard alone: While cardboard is a good eco-friendly option, it doesn’t provide the same protective, molded fit that pulp does. Bottles are safer from impact in molded pulp inserts designed specifically to hug the contours of each bottle.

- More Accessible Than Bamboo: Bamboo is eco-friendly, but it’s generally more costly to produce. Molded pulp offers a more affordable alternative that’s just as environmentally sound.

Ready to Make the Sustainable Switch?

Choosing molded pulp packaging is a straightforward, effective step toward greener practices.

If you’re looking for eco-friendly bottle packaging that’s in stock and ready to ship, check out our range of molded pulp options at our partner, [WineShippingBoxes.com].